Aerospace Grade Axial Grooved Heat Pipes

EntropyX has the ability to be a supplier of the aerospace grade axial grooved heat pipes throughout the entire industry chain. We can supply various types of reentrant grooved heat pipes, including normal temperature 3D aluminum ammonia heat pipes and low-temperature grooved heat pipes with a gas storage.

Specifications of Grooved Heat Pipes

Type |

Specifications |

Series |

Code |

Usage |

Maximum Heat Transfer Capacity(W·m) |

Reentrant Grooved |

Φ8(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-O1 |

EX-AGHP-O1-Φ8(Ω) |

externally bonded |

58 |

Φ10(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-O1-Φ10(Ω) |

externally bonded |

164 |

||

Φ15(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-O1-Φ15(Ω) |

externally bonded |

430 |

||

I-shaped Grooved |

30×Φ10(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-G1 |

EX-AGHP-G1-30XΦ10(Ω) |

externally bonded/ embedded |

164 |

40×Φ15(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-G1-40XΦ15(Ω) |

externally bonded/ embedded |

430 |

||

50×Φ18(Ω) aluminum ammonia grooved heat pipe |

EX-AGHP-G1-50×Φ18(Ω) |

externally bonded |

430 |

||

30×Φ19.1(Ω) aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-G2(A) |

EX-AGHP-G2-30×19.1(Ω)A series |

embedded |

164 |

|

30×Φ24.1(Ω)aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-G2-30×24.1(Ω)A series |

embedded |

290 |

||

30×Φ29.1(Ω)aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-G2-30×29.1(Ω)A series |

embedded |

430 |

||

30×Φ39.1(Ω)aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-G2-30×39.1(Ω)A series |

embedded |

817 |

||

40×Φ14.1(Ω) aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-G2(B) |

EX-AGHP-G2-40×14.1(Ω)B series |

externally bonded/ embedded |

374 |

|

Rectangular Grooved |

17.4×9.1(Ω) aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-J2 |

EX-AGHP-J2-17.4×9.1(Ω) |

externally bonded/ embedded |

115 |

25×12(Ω) aluminum ammonia grooved heat pipe(double holes) |

EX-AGHP-J2-25×12(Ω) |

externally bonded/ embedded |

277 |

||

Phase Changed |

60×9.1(Ω) aluminum ammonia grooved heat pipe(five holes) |

EX-AGHP-T5 |

EX-AGHP-T5-60×9.1(Ω) |

externally bonded/ embedded |

210 |

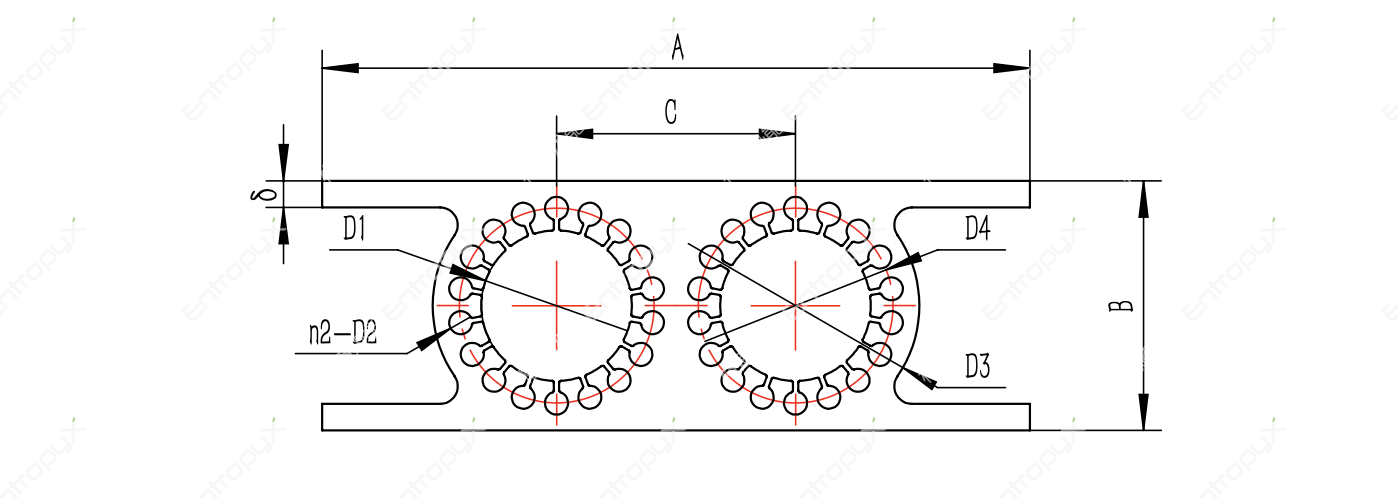

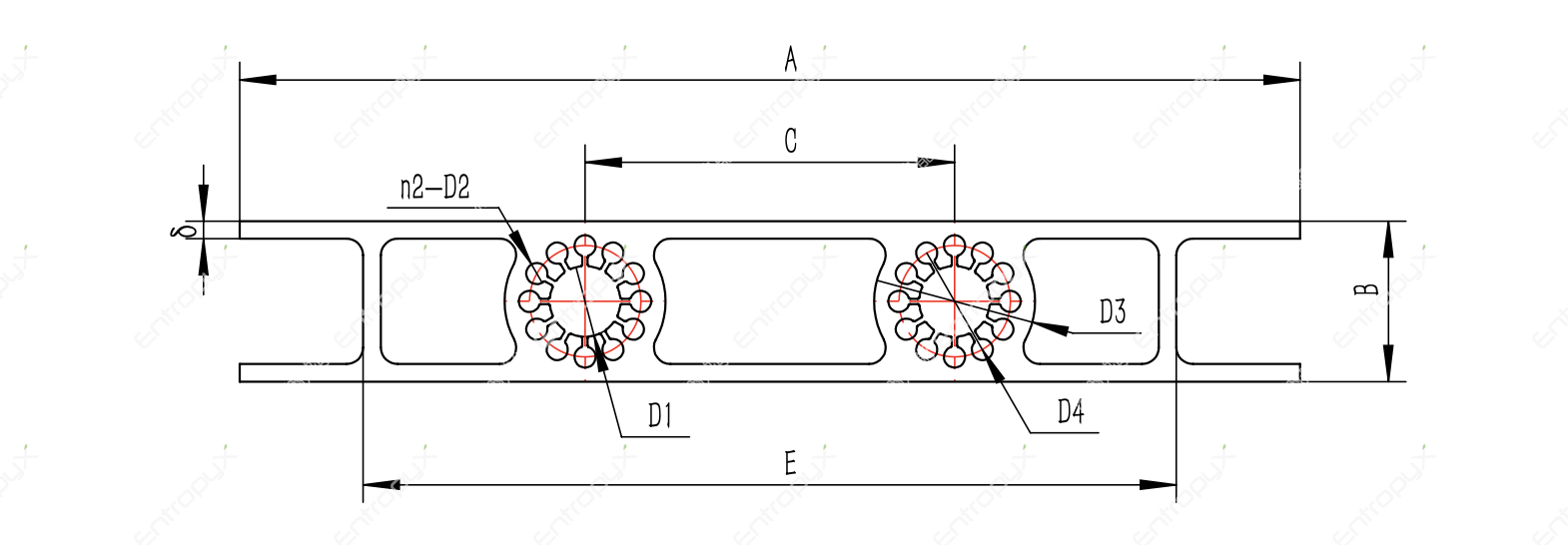

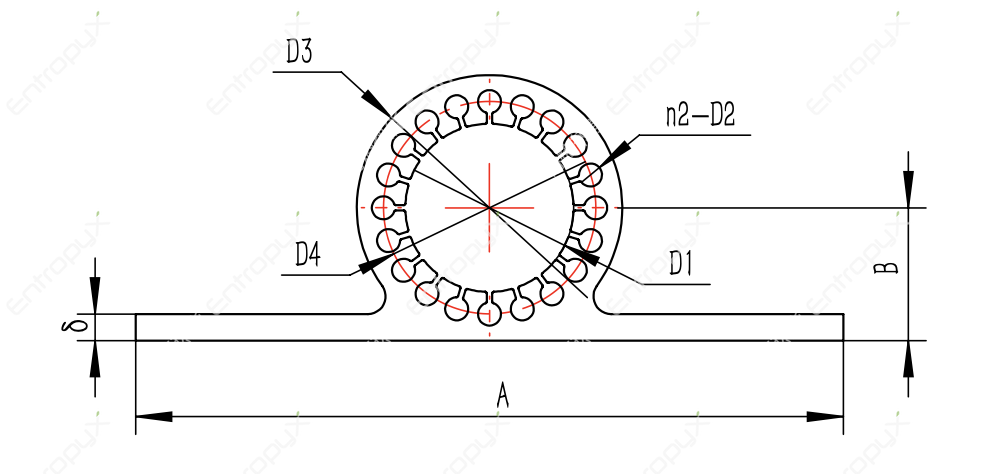

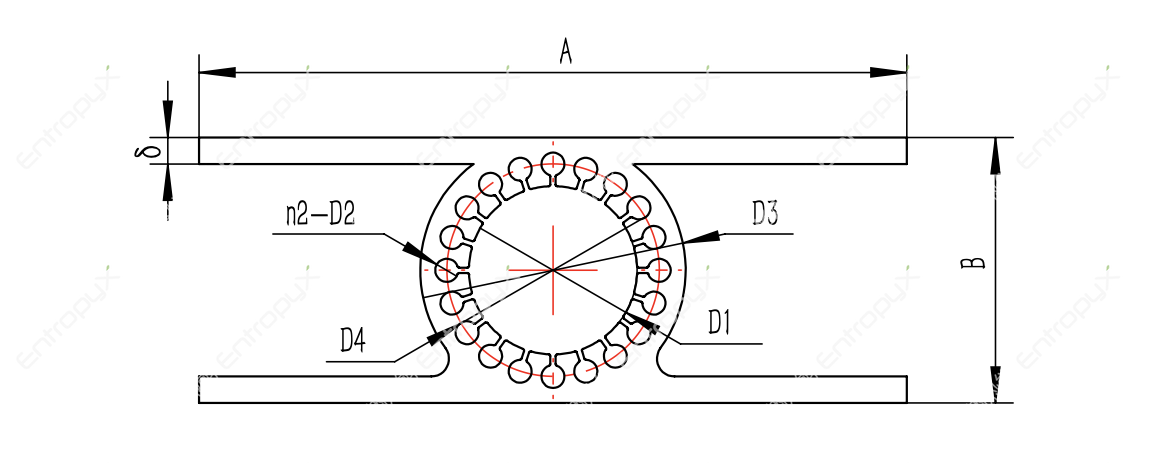

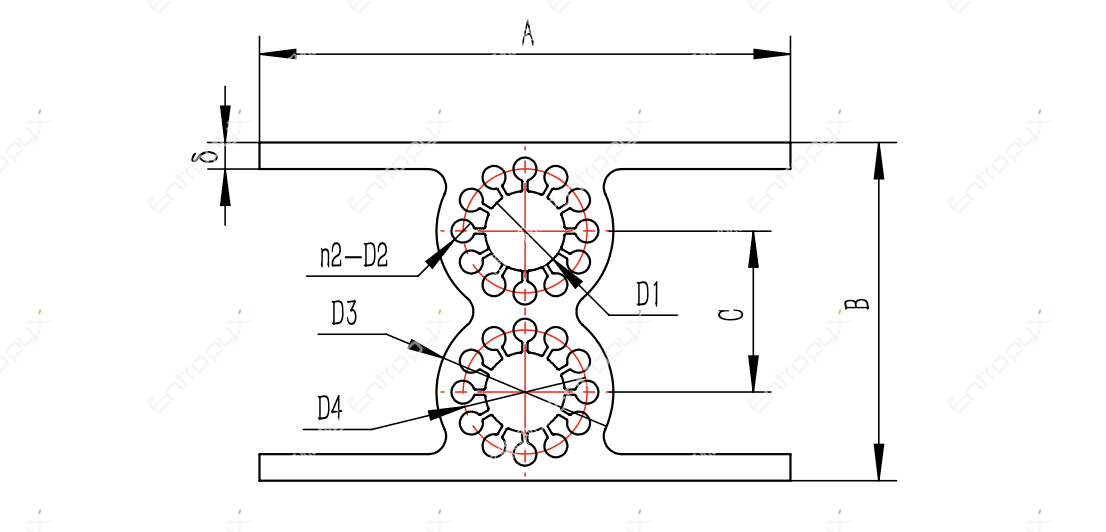

Size Identification

| EX-AGHP-O1 | EX-AGHP-G1 | EX-AGHP-G2(A) |

|

|

|

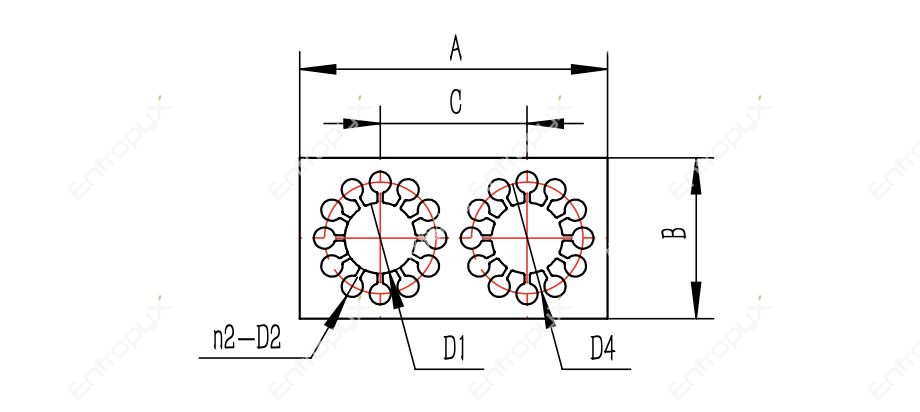

| EX-AGHP-G2(B) | EX-AGHP-J2 | EX-AGHP-T5 |

|

|

|

Heat Transfer Capacity

Parameter of Grooved Heat Pipes

Name |

Parameter |

Material |

6063 T5 aluminum alloy |

Specifications |

Reentrant, I-shaped, Rectangle, Phase Changed |

Form |

section:select according to the spectrum, other forms can be customized shape:user defined(straight pipes, 2D bends, 3D bends) |

Surface Treatment |

natural color, trivalent/hexavalent chromium passivation, anodizing, nickel plating, etc |

Maximum Length |

conventional products ≤ 3m, other lengths can be customized |

Bending Radius |

6 times the outside diameter, the curved part needs to be removed with fins, without obvious distortion, and with no significant impact on performance |

Mechanical Interface |

can be customized |

Accuracy |

length tolerance range (-5mm~0mm), straightness better than 0.2mm/500mm, flatness better than 200mm × 200mm:0.1mm |

Working Fluid |

Ammonia (normal temperature heat pipe), ethane (low temperature heat pipe), purity ≥ 99.9999% Other working fluids such as propylene, ethane, nitrogen, etc. can be customized ensuring high vacuum (<10-5Pa) and high accuracy (± 0.01g) |

Temperature |

working temperature range [-60 ℃,+80 ℃] storage temperature range [-65 ℃,+90 ℃] (using ammonia as an example) |

Heat Transfer Capability |

the actual heat transfer shall not exceed 50% of the theoretical maximum heat transfer capacity |

Ultimate Heat Flux Density |

evaporation section 7W/cm2, condensation section 5W/cm2 (using ammonia as an example) |

Mechanical Property |

sinusoidal vibration 5~25Hz: +/-10mm sinusoidal vibration 25~100Hz: 25G random vibration 20~2000Hz: 30.7Grms constant acceleration: 35G 20000 times pressure cycles between 0.1~4.2MPa burst pressure ≥ 20MPa |

Thermal Property |

1000 times thermal cycles between -50℃(1min)~+80℃(1min) 5 times thermal cycles between -70℃(2hours)~+120℃(2hours) |

System Leakage Rate |

≤5×10-12Pa·m3/s |

Service Life |

on orbit ≥ 15 years, single hole failure efficiency of 50 fits ground storage life ≥ 5 years |

Advantages of Aerospace Grade Axial Grooved Heat Pipes

Application Cases

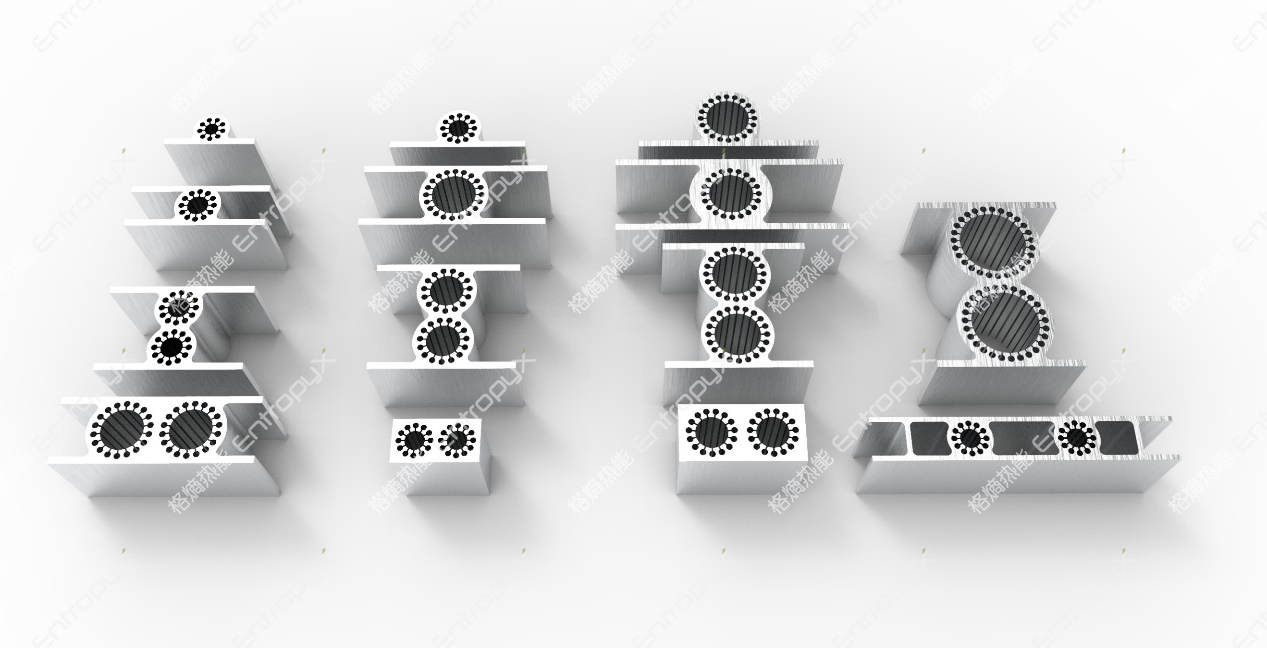

Profile Sections of Axial Grooved Heat Pipes

Profile Sections of Axial Grooved Heat Pipes

Embedded Axial Grooved Heat Pipes

Embedded Axial Grooved Heat Pipes

Externally Bonded Axial Grooved Heat Pipes

Externally Bonded Axial Grooved Heat Pipes

Low Temperature Axial Grooved Heat Pipes

Low Temperature Axial Grooved Heat Pipes